Fathers and Sons, Part 2

Many of the best cigars in the world—and much of the tobacco that goes into them—are the product of father-and-son teams. In our second installment of this story (see the August 2006 issue for the first article), we continue our look at the personalities behind some of the world's greatest cigar brands and the tobacco used in their creation.

Carlos Fuente Sr. + Carlos Fuente Jr.

The June heat is unrelenting, even under the thatched gazebo near the entrance to Chateau de la Fuente. Peacocks caw in the shadow of the royal palm trees that seem to be everywhere on this gorgeous tobacco farm where every rock lining the roads is painted bright white, where each detail is carefully attended to in this oasis where some of the world's most sought-after tobacco is grown.

No father-son team is as famous as that of the farm's owners, Carlos Fuente Sr. and Carlos Fuente Jr. The two men run a business that makes some 35 million cigars by hand each year, among them the Fuente Fuente OpusX Double Corona, Cigar Aficionado's 2006 Cigar of the Year.

They sit down at a small, simple table that stands on the tiled floor of the gazebo. On its top are a thermos of rich, black coffee, a few dozen cigars and a wooden ashtray. As Carlos Jr., known as Carlito, reaches for a dark OpusX, it's easy to see his resemblance to his father. Each man has a thin mustache, and neither looks his age. The elder Fuente, 71, has a head of thick hair for which men 20 years his junior would kill, even though it's mostly white. The son, 52, is showing flecks of gray in his black hair, but his eyes sparkle with the enthusiasm of youth. The bond between the two is evident.

It's a cigar-making bond that goes back to a previous generation. Arturo Fuente, Carlos Sr.'s father, created A. Fuente & Co. in 1912 with a group of partners in the Ybor City section of Tampa, Florida. The business burned down in 1924, and it wasn't until 1946 that Arturo reopened it behind the family's house. It was a small, bootstrap operation, far from the juggernaut that is Fuente today.

"Cigarmakers would leave their day jobs in other cigar factories—there were hundreds around Tampa—and then they would go visit my grandfather and make cigars with him at night," says Carlos Fuente Jr. "They didn't charge him," adds Fuente Sr. "They would do it out of friendship. That's the way my father started."

Carlos Sr. had little money growing up, and soon developed a strict work ethic to make ends meet. "I was maybe eight years old, and I always liked to earn my own money. I shined shoes in the street, I worked in grocery stores, a pharmacy, and when I became a teenager I used to get off school at 3:30 and I used to start working at four at the pharmacy, until 11 o'clock at night. I would get up at two, three o'clock in the morning: I had a newspaper route, and then at eight o'clock in the morning I used to go to school. I'm used to working seven days a week my whole life."

When he was 16, Carlos Sr. took a job as a baker because his father couldn't afford to employ him at the factory, although he had been making cigars off the payroll for his dad since he was 10. Baking paid well for the time—with overtime, $160 a week—but after marrying at age 18 and having a child a year later, he yearned to work full-time in the family business. In 1957, he realized that goal, quitting the bakery job even though his father still couldn't afford to pay him a salary. Fuente Sr. made do by getting his wife a job at another cigar factory and by selling cigars on the weekends.

After Carlos Sr. took over the business in 1958 (Arturo stayed on in a limited capacity until 1965), the Fuente factory was extended to include practically every room in Arturo Fuente's Ybor City home. "We took the whole house over," says Fuente Sr., who by now was able to draw a weekly paycheck of $40. "I just left my father and my mother one back room and an area to cook. That was all they had left. They had a living room, but when we had to blend the tobacco, we had to get all the furniture out of the living room and out on the street. The kitchen we used to cellophane cigars."

Young Carlito grew up surrounded by the cigarmakers. "I was born in the business, and as far back as I can I sat on cigarmakers' laps, and watched them roll in the back of my grandmother's house," he says. "It was a family business, and I thought everybody was family. I lived inside the factory until I started going to school."

Now that he was running the family cigar business, Carlos Sr. started to buckle down. He began traveling to Miami to extend the realm of the company, and sold on credit for the first time. The business was moved from the home to a proper factory, then to a larger plant. Carlos Sr. never seemed to stop working. "One time it was three weeks without coming home. Three weeks. So my wife came with Carlito on one side and a bag on the other side, and said, 'Well, if you're not coming home I'm moving in here with you.' " He had little time to pause, as he did many of the jobs himself, including maintaining the machinery. "Now, there's nothing in the factory I can't do."

When the boss knows everything about a business, he can be hard to please. "I wasn't easy to work with a lot of times. I used to have sort of a temper, and I liked things to be right." Carlito smiles, and offers a correction. "Perfect," he says, drawing a grin from his father.

One day in the early 1960s, when Carlos Sr. visited the factory, he grew incensed at the poor quality of the cigars. "I threw them against the wall," he says. "I got my keys. I told my father, 'You keep the damn business—I'm leaving here.' I said, 'Close the place.' I told everybody, 'Get the hell out of here.' Everybody."

Carlos Sr. eventually returned to the factory, and rehired the crew. Quality improved. With Carlos Sr. working such brutal hours, the amount of time Carlito spent with his father was limited during his childhood. "My father would be working 18 hours a day," he says. "My grandfather [acted as] my father. He would tell me stories about Cuba."

The A. Fuente brand had always been made by hand in Tampa, but with rising labor costs and a shrinking pool of cigarmakers in the United States, Carlos Sr. tried producing Flor de Orlando and other brands offshore in the mid-1970s, with poor results. In Nicaragua, their factory was burned to the ground, and fire also claimed a factory in Honduras. Carlos Sr. tried training young cigar rollers in the 1970s in Tampa, but he and his son couldn't retain the labor at the prices they could afford to pay. "I saw there was no future [in Tampa]," says Fuente Sr. The only future we got is handmade cigars, or go totally mechanized. And I don't like that, and that's not our trade. We had to move. My son told me, 'I want to stay in the business.' I said the only way we're going to go is as a family. We'll keep it in the family business."

In 1980, the two left the comfort of Tampa for the wilds of the Dominican Republic, which was a far rougher place then than it is now.

"There was nothing here," says Carlito, who left behind a Porsche and a Jaguar when he moved. His father left his house, which was paid for, and sold everything he had to fund the new business. "I cashed in my insurance, mortgaged my house, then I asked my son, 'How much you got?'"

Carlito had spent time in the Dominican tobacco fields during the mid-1970s at the behest of his dad. "When I started in the business, I learned what it's like to manufacture, but I wanted my son to go further than I did," says Fuente Sr. "I wanted him to work in the fields."

In the Dominican Republic, the two worked side by side. They ate lunches together every day, smoking cigars and drinking Beefeater Martinis, and strategizing.

"Our family has always been close," says Fuente Sr. "I never recall having an argument with my father, and I never recall having an argument with my son." Not that they always agree. "When we started this farm," he says, gesturing with his arm, "we didn't need it. [But] look what he's done—he's taken this business to the next level. What my son has done is tremendous."

Just as Carlos Sr. took Arturo Fuente beyond the small borders of Ybor City and into national s, Carlos Jr. transformed the cigarmaker with the creation of Chateau de la Fuente. There the Fuentes grew Cuban-seed tobacco under shade in the Dominican Republic and used it as the wrapper on a novel project, the Fuente Fuente OpusX cigar. Dominican wrapper of this type had never been a commercial success, and was certainly never ballyhooed as a crowning element in a cigar. While the Fuentes had a hit from day one with consumers, the unique project caused quite the controversy with others in the industry.

"They said we were crazy, they said we were going to have a flop," says Carlos Sr., recounting what he heard from his contemporaries. He furrows his brow. "I knew that it could be done. There's nothing in this world that can't be done. I knew we didn't need it, but if that's what he wanted to do, I went along with him."

Doubt brought the two even closer together. "The more people said it couldn't be done, the more we wanted to do it," says Fuente Jr. "The more they said it couldn't be done," adds the father, "the harder we worked."

Fuente now makes more handmade cigars than any other family-owned company, and its size rivals that of the industry's corporate giants, Altadis U.S.A. Inc. and General Cigar Co. Despite the growth, Fuente is still very much a family affair. The company enjoys the luxury of not explaining its decisions to shareholders. The cigar blends are secret and are not written down. "Only my father and I know," says Carlito. The family hoards tobacco, putting much of its profit into the leaves it uses to make cigars. "We have six, seven, eight years of tobacco in inventory," says Fuente Sr. "It doesn't make business sense," says Fuente Jr. "My father always told me, you can run the cigar business with your heart, not with pen and paper."

Carlos Sr.'s daughter, Cynthia Fuente-Suarez, is also closely involved in the business, as is her husband, Wayne Suarez, who has been a part of the Fuente organization since 1992. "This is not a business to the Fuentes," Suarez says simply. "It's a way of life."

As the sun begins to sink lower in the sky, the heat relenting slightly, Carlito reaches for another one of his strong cigars. "I've been by my father's side the entire time," he says, looking at his dad with pride. "I can't imagine doing anything else."

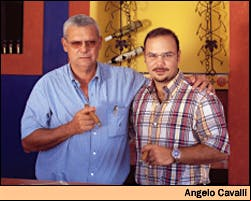

John Oliva Sr. + John Oliva Jr.

If following in the footsteps of a successful businessman can be difficult, living in the shadow of a legend is far harder. The late Angel Oliva Sr. is one of the most revered men in the history of cigars. The hard-driven Cuban etched his name in the cigar history books when he bought much of the last pre-embargo Cuban tobacco crop—some 2.5 million pounds worth—and sold it for fair prices despite a U.S. embargo that suddenly made the leaf priceless. Known for working extremely long hours and patiently sorting tobacco until he felt it was perfect, he was the antithesis of an easy boss.

John Oliva Sr. (left) and John Jr. John Oliva Sr. (left) and John Jr. |

Oliva came from a huge family ruled by a tough father. Survival meant work, and as a young boy Angel collected manure for two cents a pound. At age 12 he left home, and eventually founded Oliva Tobacco Co., in 1934. In the late 1950s, he bought his own farm in Cuba, fulfilling a dream.

"When I was 10, we went to his farm in Pinar del Río," says Angel's son John Oliva Sr., sitting in the Columbia Restaurant in Ybor City. In this city built on cigars and tobacco, a street just steps away from the Columbia has been recently renamed Angel Oliva Sr. Street. "We used to stay at a little apartment on the farm. He'd say, 'Come here, I want to show you this. Aren't you interested?' I'd say, 'No, I don't want to look at tobacco.' But at 10 years old, he was working his ass off. He was picking up tobacco leaves, he was working—he had no choice. Let me tell you what, he was a hard worker. He was a hard worker all his life."

To describe his father's work ethic, and perfectionist streak, Oliva Sr. describes a marathon day spent repacking an entire shipment of 124 bales of candela wrapper—with only his family to help. "We repacked all that tobacco, carton by carton. Started at eight in the morning and stopped at three in the morning. I fell asleep on the way to bed," says Oliva Sr. "Let me tell you, he was 56, I was 21. I did the heavy work, but he worked right alongside me."

Angel Oliva had the look of a kindly grandpa in his later years, but he was a tough businessman. "He was on a rampage in Jalapa [Nicaragua]," says John Sr., describing an incendiary negotiation with another tobacco man named Pepe Cura that left the latter clearly out of sorts. John Sr. found Cura sitting on the hood of his Toyota, a pair of eyeglasses perched high above his eyes, a flustered look on his face. John asked him what was wrong. "He said, 'I can't find my car, and I don't know where the fuck my glasses are.' I said, 'Pepe, your glasses are on your forehead and your car is under your ass.' He said, 'Damn, your old man is really bugging me today!'"

As a younger man, Oliva Sr., now 64, wanted no part of Oliva Tobacco. In 1970, he was quite comfortable working in the computer industry. His older brother, Angel Jr., also didn't want in. So Angel Oliva Sr. pulled his trump card to persuade his son John to trade in PCs for petit coronas.

"The old man had to fake selling the business to get me in there," he says. A buyer came in, a deal was set, and in what Oliva Sr. calls "the greatest charade ever," Angel convinced his son he was prepared to sell to a man from Holland. John Sr. began working for his father. (Eventually, Angel Jr. would, too, starting in 1974.)

John Oliva Jr. didn't need as much convincing as his dad. He relished his early trips to Ecuador with his grandfather, and after trying the seafood business for a time, he eagerly entered the family tobacco trade, in 1992.

"He and I get along because I'm exactly like my mother," says John Jr. of working with his dad. "We're complete opposites. He doesn't want to look at tobacco and I don't want to look at the computer," he says with an easy laugh. John, a 42-year-old who looks much younger, sports a much more laid-back personality than his dad. He even speaks in a hushed voice, a few octaves lower than John Sr.'s, which booms with authority and enthusiasm.

The elder Oliva beams with fatherly pride when speaking about his son's talents in the tobacco business, which he claims outstrips his. John Sr. sees some of his father in his son. "John got more of my father's love of tobacco than anybody else," he says. "I love the business. [But if] I'm looking at tobacco, I look at it, I say, 'Here you go, it's worth this.' He actually likes it. He handles every sample himself. There's not a lot of people like that. He's much more like Dad than I am."

John Sr. is particularly complimentary of the way his son cases tobacco, a dreary process that, when done properly, involves careful handling of each tobacco leaf so it can be treated with water. "When he cases the tobacco, the acceptance rate goes up. Why? Because it's properly cased," says John Sr. "He takes every leaf at a time and separates them so it gets the water properly. That takes an enormous amount of patience."

He describes how one of their workers in Ecuador has been casing tobacco nearly his entire life. "This guy was born in tobacco, and his samples are OK. But they're not like his," he says, his arms crossed in front of his broad chest, nodding to his son. "And I'm not saying it because he's here. It's a fact. The acceptance rate ain't there when I cased."

It must be tempting to skip a few leaves when doing the process one leaf at a time. John Sr. fields the question quickly. "Can't do it," he says. "Those would be the first three or four leaves the customer would touch."

So how does one follow in the footsteps of a legend?'

"You want to know what the trick is? Don't try to do it. I never did," says Oliva Sr. "Don't ever try to follow your dad's footsteps—make your own. I don't care who your dad is. I can tell you right now, my father is an unusual man. He created a business from nothing. I can't tell you I ever did that. My goal was to try to make it as big as I could, make it bigger and more profitable. You do what you do best."

Gilberto Oliva Sr. + Jose Oliva

Oliva Cigar Co. has been growing tobacco in Nicaragua for decades. The Miami Lakes, Florida, company (which is not related to the Oliva Tobacco Co. in Tampa) branched out into cigar manufacturing 11 years ago. It now sells a variety of cigars bearing the family name, from the bargain-priced Oliva "O" Classic Olè (which was one of Cigar Aficionado's Top 25 Cigars of the Year) to the higher-end Oliva Master Blends, a new version of which comes out every year. Company vice president Jose Oliva ed the family cigar and tobacco business when it started making cigars. He was 22 years old, fresh from studying marketing at St. Thomas University in Miami, and he thought he could teach a few things to his father, family patriarch Gilberto Oliva Sr., who was then 64.

"Working with my father is a thing that has evolved," says Jose, who is now 33. "Eleven years ago, there was a good deal of frustration, me thinking things needed to be done a certain way. Now, it's pure iration and appreciation for him."

When the Olivas first began making cigars, they tried to emulate the popular brands of the day, putting light-colored Connecticut-seed wrappers around a mix of Dominican and Central American tobaccos. They failed to find an appreciative audience.

Salvation came from the family's disdain for taking on debt: the company turned to Gilberto's large inventory of aged Nicaraguan tobaccos and began making puros. The change worked well, as Americans were growing more enamored with rich Nicaraguan tobacco leaf.

As a young man, Jose didn't understand the value of having bales of tobacco piling up in inventory, not making money. "I, being very young, wanted to see additional money put into marketing, additional money put into packaging. He wanted it all to go into tobacco," he says. "There was a tremendous amount of what I thought I knew."

Hendrik + Henry Kelner

It's early in the afternoon on a sunny Monday in Santiago, Dominican Republic. Lunchtime is over, and business is set to move into the spacious corner office of the boss, Hendrik Kelner. Cigars are lit, and he and his son sit down in front of an ashtray that can hold a dozen cigars. On the smoking agenda for the afternoon is a pair of Zino Platinum cigars, the Barrel and the Grand Master, plus a new size that may end up at the Retail Tobacco Dealers of America trade show, five weeks away.

Hendrik, 60, is a tobacco man by blood, and his 33-year-old son is no different. How long has he worked with his dad? "All my life," says Kelner Jr., who goes by the nickname Henry. "In the '80s, I worked during the summer, in the '90s, I worked part-time, and since 1993, I work full-time." Today, the father oversees the three cigar factories that comprise the entire operation that makes Davidoff, Avo and a host of other cigars, while the son is manager of Cigars Davidoff, the factory where Davidoffs are rolled.

The Kelners come from a long line of tobacco men. "It's a tradition of the family," says the elder Kelner. "My father [Klass] worked in tobacco. He started very young in Amsterdam, and came to the Dominican Republic in 1933. My father never had a cigar factory—the Kelners traditionally worked in raw materials, in Brazil, Paraguay, Indonesia and the Dominican Republic."

Hendrik Sr., known to the cigar world as Henke, has one of the most sophisticated palates in the industry. A veritable tobacco scientist, he can speak for entire afternoons about tobacco and rhapsodize at great length about the characteristics of whatever he is smoking.

"We always have lunch in the factory," says Henke. "After lunch, we try to have quiet, and it's a pleasure because we take our cigars and we say, 'What do you think about the taste? The aftertaste?' We have coffee and Cognac, and we compare. And when we agree, we are happy." Cigar smoking is work for Henke, who takes detailed notes on the cigars and how they stimulate the various flavor receptors on the tongue—salty, sweet, bitter and sour. "We have a chart," he says, describing the lengthy process he, his son and close associate Eladio Diaz go through when testing cigars. "The blend for us is not a formula.

"Normally when I smoke, it's my job," he says in his heavily accented English. "Sometimes, I smoke for pleasure. When I really like a cigar, after I smoke half, I say, 'This half of the cigar is for pleasure. No writing, no talking, just 'conjo, que buelo esta cigar,'" he says.

His son, a smaller, quieter version of Kelner, is humbled to follow in his father's footsteps. "I'm not as gifted as my father in of palate," he says. "I still have a long way to go." Kelner praises his son's progress in the trade. "He learns fast, but in the cigar business you learn every day."

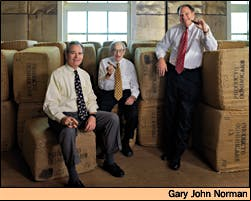

Stanford, Eric + Bobby Newman

Sometimes being the son of the boss means an easier path to the top of the company, but Stanford Newman had a challenge working for his father. Stanford, 90, the chairman of J.C. Newman Cigar Co., spent most of his career working in the large shadow of his domineering father, Julius Newman, who second-guessed nearly every move his son made until his death.

Bobby (left), Stanford and Eric Newman Bobby (left), Stanford and Eric Newman |

J.C. stands for Julius Caesar, and the man more than lived up to his name. (An èmigrè from Hungary, he chose the middle name himself, when he ed to vote in the United States.) J.C. was a self-made man who created a tiny cigar company in 1895 with $50 he borrowed from his family and an order for 500 cigars from the local grocer. The company was a one-man cigar factory, operating out of a barn behind the family home near Cleveland. At the time it was one of 42,000 cigar factories in the United States, and one of 300 in Cleveland alone.

J.C. Newman Cigar Co. survived the post-1950s industry fallout that caused most of America's small cigar companies to close, consolidate or move offshore. While U.S. cigar factories are rare today, the firm, now headquartered in Tampa, still makes cigars by machine in the upper floors of its headquarters, as well as serving as the U.S. distribution arm for the cigars made by hand by Tabacalera A. Fuente y Cia., which include the Cuesta-Rey and Diamond Crown brands owned by the Newmans. Stanford works alongside his sons: Eric, 58, is the company president and Bobby, 55, is executive vice president.

Back in 1914, J.C. Newman was making successful brands such as the five-cent Judge Wright, and the company owned the largest cigar factory in Cleveland. In 1934, Stanford began working for his father as the downtown Cleveland salesman, and three years later he ed the company full-time. He had reservations.

"If I could have found a job working for any other place, I wouldn't have worked for him. It was much too difficult," says Stanford, sitting in his conference room in Tampa. "My father was short, and he had a Napoleonic complex. He wanted it his way."

When Stanford was a child, his father had a habit of bringing a cane to dinner and pounding it to keep order and when he wanted attention. As an adult, Stanford discovered that J.C. could be just as demanding at the office.

"He used to go at six in the morning to the post office and read the mail. And then he would write on the bottom of the letters how I should write back," said Stanford. "He thought I never grew up."

The examples of J.C. meddling with Stanford's authority at the company are legion. In 1948, Stanford came out with a five-cent cigar called Cameo Bouquet. He and his father made a sales call, resulting in a deal to move 500,000 of the cigars a week to one . Stanford left the room, and J.C. told the buyer that he was raising the price of Cameo cigars by one cent. When Stanford returned, the buyer cancelled the order. Other prospective buyers followed suit when J.C. tried the same tactic. The surprise price hike ended up costing the company half the Cameo business.

Soon after, at a time when cigar-making machines were in short supply, Stanford purchased 10 or them, only to have his father trade them for some Puerto Rican tobacco while he was out of town. When packed, the tobacco curled, which made lumps in the cigars. To deal with the new tobacco, Stanford bought a conveyor belt and had workers straighten the tobacco and put it in large cases, rather than into piles. When he returned from another trip, the cases were gone; his father had ordered the tobacco unpacked and put back into piles, undoing Stanford's work.

In 1958, Julius died, leaving the company to Stanford, his younger son, Millard, and the Newman family. As the decades went on, the cigar market shrunk and the family business suffered, which resulted in tension within the family.

"We had 14 other relatives [in the business]. It was very difficult. The cigar industry was going down, and our sales were going down," says Bobby. "In 1985, Eric and I went to Dad and said either we've got to buy our relatives out or they have to buy us out."

Stanford and his sons chose the former strategy, and the three were then in control. Stanford made it a point to manage differently than his dad had.

"I wanted to give responsibility to my sons," says Stanford. "I wanted them to do things themselves."

The next generation is already making an impact on the family business. "I've been in the business since I was nine," says Drew Newman, Eric's 25-year-old son. Displaying a knack for computers, Drew helped create the popular Fuente and Newman Web site, cigarfamily.com, when he was 14. "I told my father we should have a Web site," he says. "Dad said, 'What's a Web site?'" Drew is now in law school at American University, and eventually intends to the company. He even designed the "M"-shaped Diamond Crown Maximus box, which has a radical design that doesn't quite sit right with Stanford.

"I didn't think much of the idea," he says simply, as his sons laugh.

Stanford is still active in the business. During a tour of the company's small cigar-making operations upstairs, he gives a freshly made cigar a squeeze, his personal way of draw-testing. "Dad goes by the feel," says Eric, a touch of wonder in his voice. "Bobby and I are the technicians of the business, managers of the business—Dad is still the visionary."

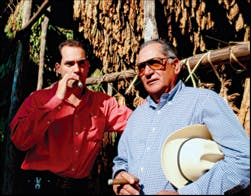

Nestor Plasencia + Nestor Plasencia Jr.

Nestor Plasencia Sr. (left) and Nestor Jr. Nestor Plasencia Sr. (left) and Nestor Jr. |

Like a pair of good basketball players, the Plasencias are constantly in motion. "We're about to spread out," says Nestor Jr., 31, speaking during his regular Monday morning sit-down with his father in Nicaragua. The two run the Plasencia tobacco and cigar-making empire, which stretches across Nicaragua and Honduras. They meet each Monday for an hour or two to strategize for the week, then scatter across the region. One might go to the fields in Jalapa, where the wrapper leaf is smooth and rich, while the other might head to Danlí, Honduras, home to one of the company's five cigar factories, or to Ocotál, Nicaragua, where the Plasencias process one of the world's largest collections of tobacco. The two are rarely in the same spot.

"We don't see each other during the weekdays," says Nestor Jr., "but on the weekends, Friday, we get together and discuss what we did for the week."

It's not an easy schedule. The two are constantly on the road, beating up their vehicles over roads that often have more bumps than the local economy. "I change my car every four years," says Nestor Jr. His father changes every three.

The elder Plasencia, 56, is proud of his son. "I feel very good," he says. "I have the privilege to have continuity in the business, the same way my father felt when he was working."

Nestor Jr. is the only one of three adult siblings to work with his father. His older brother, Gustavo, is an interior designer and his older sister, Alina, is a dentist. (His younger brother, Josè Luis, is only 13. "Maybe my younger brother will us. We need some help," Nestor Jr. says, showing the trademark Plasencia sense of humor.)

The elder Plasencia is a legend in the business. "Moving, moving, moving," is one of his favorite sayings, often uttered after clapping his hands for emphasis as he chugs from one spot to the next, showing off his remarkably broad business. He's ittedly antsy when standing still. "Frustrated," he says in one of his compact, brusque answers, when asked how he feels when he's not in motion. A workaholic, he does other business while his son answers questions during a t interview. "It's part of my personality," Nestor Sr. says with a smile. "I don't stay in one place for too much time."

He churned out more than 30 million cigars a year during his busiest days of the cigar boom (most of them brands made under contract for other companies) and has always been a big grower of tobacco. In recent years, he switched from growing primarily filler tobacco to growing wrapper, which is much more profitable. He plants tobacco on the volcanic island of Ometepe, Nicaragua, in San Agustín, Honduras, as well as in the traditional areas of Central America.

The Plasencias are among the most successful tobacco men, but only 20 years ago business was quite poor. Nestor Sr.'s crops were regularly ravaged by blue mold, and without tobacco to sell he had a hard time making money. Plasencia likes to joke about a banker who financed his three businesses in the mid-1980s, a stressful job to say the least. "I went to look for the banker at the bank, and he wasn't there. He was in Houston, at the hospital, getting a triple by," says Plasencia. A month later, the tobacco grower paid a visit. "He said, 'Every by had a name,' and each name was one of my companies."

Business began to improve in 1990. "At that time, we started growing [tobacco] varieties that were more resistant to blue mold, and Swisher decided to [have us] make Bering and La Primadora in Honduras," says Nestor Sr. The cigar boom soon followed, and the Plasencias went from struggling to surging.

Nestor Jr. is a born-and-bred tobacco man, like his father. "I started working every holiday when I was a little kid, in the farms and factories," he says. Since he was seven years old, time off from school meant it was time to work with dad. In 1998, out of school, he ed his father full-time.

Nestor Jr. always knew this was the route he would take, even though his father never pushed him into the tobacco business. "One of the things my father always told us—you need to do what you like to be good. You have to put ion in it."

"It's a big example to follow," says the son of his father. "My dad is the guy I respect the most in the tobacco industry. Every day is a learning experience."

Fernando León + Guillermo León

More than a century ago, Eduardo León Jimenes began making cigars in the Dominican Republic. The firm he created in 1903 is the oldest cigarmaker in the Dominican Republic, and today its parent company, Empresas León Jimenes, has annual sales of more than $600 million. Empresas León Jimenes brews Presidente beer, owns a bank, makes cigarettes and rolls remarkable cigars. Eduardo's descendants carry on the cigar tradition.

Fernando (right) and Guillermo León Fernando (right) and Guillermo León |

"Now, I'm in charge of the heritage," says Eduardo's grandson Guillermo, in his slow-cadenced voice, which has a touch of gravel. "It's heavy on my shoulders." The 46-year-old León, a tall man with chiseled good looks, runs La Aurora S.A., the parent company's cigar business, which includes core brands Aurora and León Jimenes, plus popular new releases such as Aurora 100 Años and Aurora 1495. He's speaking on a quiet holiday in the Dominican Republic, sitting in his spacious office inside the gleaming complex that is La Aurora in Santiago. Most conversations take place here around a coffee table, which is surrounded by a large couch and chairs. To the left is a cabinet of cigars, some dating back to the 1970s.

"I feel very proud, because I have someone who I can trust 100 percent because of his knowledge, and who I know is going to guide me on the right track," says León. "That's an advantage." His guide is his father, Fernando León Asensio, who ran Aurora with his three brothers. Although the 84-year-old is officially retired from the cigar business, he still looms large over the company's operations. "He comes in two or three times a week, and he goes to the farms still to see the crops," says Guillermo, "and he still smokes five cigars a day." The smoking is not always recreational. "Anything that he finds, he tells me right away. He's part of the tasting ."

The elder León is a stately, white-haired gentleman who speaks in a crisp, booming baritone. His father gave him an unusual introduction to the cigar business. "The first thing my father did to expose me to the business as a youngster was to buy me a white linen suit, then take me out to the fields just ready to be harvested. Then he asked me to walk across it several times so I could get acquainted with the raw materials for cigar manufacturing," says Fernando León. "You can imagine how my new linen suit looked at the end of the walk. I was never to forget the experience.

"No one can make a good tobacco man by imposing," says the elder León. "I really think it is a matter of genetic heritage. This is a trade that cannot be truly loved unless one is born into it. There are no institutions that I know of that you can attend and get a degree on this fascinating world of tobacco."

The Leóns are not the only family business connected to La Aurora cigars—the company that distributes its smokes, Miami Cigar & Co., has a father-son team, Nestor and Daniel Miranda, involved in the business as well.

Guillermo is humbled by his family's history, and hopes to take the company further, as his father and three uncles did before him.

"The four brothers," Guillermo says, "they worked as hard as my grandfather. It's like a ladder—my grandfather started [climbing] and walked two steps. Then they did three steps, or four or five. Now I have to keep going."

Father + Son Teams of the Past

Some of today's best-known cigar stars were trained by their fathers. Ernesto Perez-Carrillo, the maker of La Gloria Cubana, worked for his father (of the same name). The younger Carrillo originally wanted to be a drummer, but when his father nearly sold the business to the Gore family, makers of Royal Jamaica, the son had a change of heart and decided he, too, wanted to be a cigarmaker.

Frank Llaneza, the storied former owner of Villazon & Co. and one of the first producers of gusty, strong cigars, inherited the Villazon cigar business (later acquired by General Cigar) from his father, Josè Llaneza. "I had to do everything in the factory," says Llaneza, describing how his father wanted him to learn each step of the cigar-making business before he retired. Manuel Quesada, the maker of Fonseca, Cubita, Matasa 30th Anniversary and many other cigars produced at Manufactura de Tabacos S.A., was trained by his father, the late Manuel Quesada Sr. Nick Perdomo Jr. once worked in tandem with his father, Nick Sr., who oversaw Tabacalera Perdomo's Nicaraguan cigar factory, while Nick Jr. managed things from the company's Miami Lakes, Florida, headquarters. Perdomo Sr. died in 2004.

Theo Folz, the chief executive officer of Altadis U.S.A. Inc., was brought into the cigar business by his father, Monte, who covered 19 states for Bayuk Cigar Co., the maker of Phillies cigars. "My father," said Folz in a 2004 Cigar Aficionado story, "was the greatest salesman I've ever known." Alfons Mayer, who once bought all of the tobacco used by General Cigar, followed in the footsteps of his father, Alfons, a major buyer of Indonesian tobacco into Amsterdam. George Gershel, who travels the world buying the tobacco for Altadis U.S.A., is also the son of a tobacco man. Chris Topper learned how to run a cigar business working with his father, Frank, who died in 1997. Today, he's the fourth generation to run Topper Cigar Co., which is 110 years old. Benjamin Menendez, senior vice president of cigars for General Cigar, learned how to make cigars working for his father, Alonso, who owned Cuba's Montecristo and H. Upmann brands. Benjamin's brother, Felix, makes Dona Flor and other cigars in Brazil. Tobacco grower David Perez, president of ASP Enterprises Inc., assumed the helm after the death of his father, Alfredo, in 2000, and sells some of the world's most prized tobacco leaf.

With all of its complexities and secrets, the art of creating fine cigars and growing rich tobacco is ideally suited to be ed down from father to son. The revival of cigar sales in the 1990s brought many a son who had sought out other ventures back into the family business, and ensured that the secrets would be ed on, each son inheriting his forefathers' secrets and trying to build on the success that came before, hoping to learn just a little more to on to the next generation that might follow in those new footsteps.